This week’s charts were surfaced by my EIP colleague Dr. Eve Hanson, who leads our research & commercialization work focused on carbon capture & clean fuels.

The first chart comes from Climeworks, one of the first major developers of “Direct Air Capture” technology (or “DAC”), which refers to big machines that capture CO2 directly from the ambient atmostphere. If you need some more background, there’s a lot more on this topic in my last piece on carbon capture & sequestration.

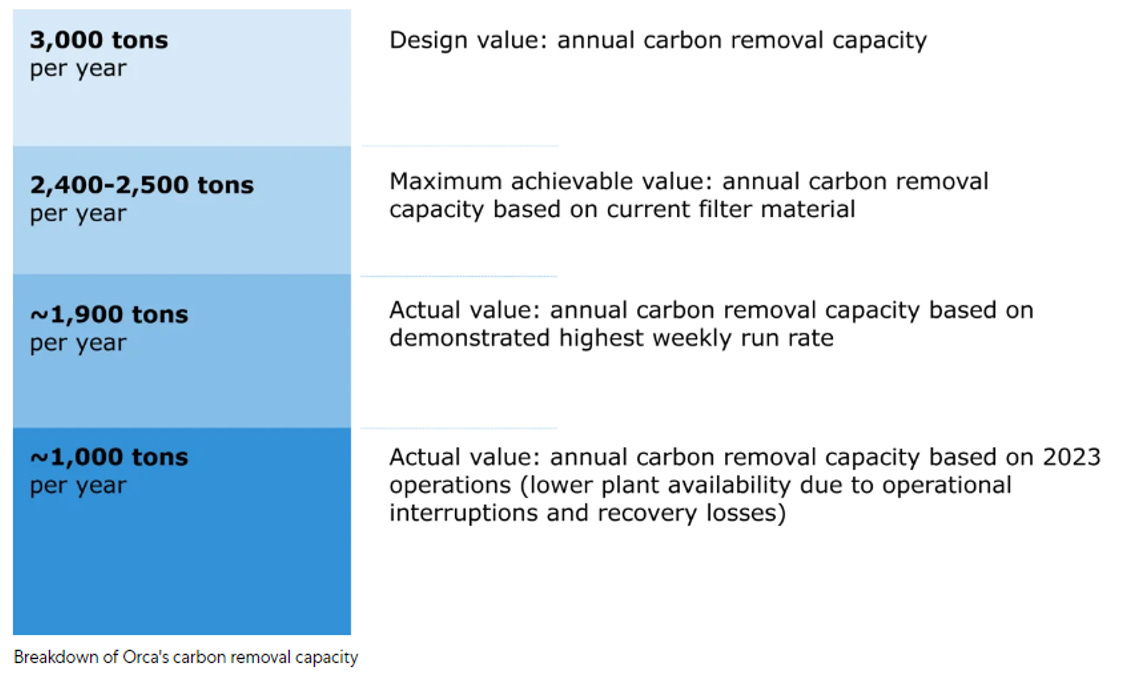

Earlier this year, Climeworks published a summary of the performance at their first real world plant, which they named Orca. For the full analysis, check out “The reality of deploying carbon removal via direct air capture in the field” (Climeworks, May 2024).

Notes:

It turns out, as just about everyone suspected, scaling up engineered carbon removal technology is really, really hard. Around the same time Climeworks published these results, I was sad to see another innovative carbon removal company (which was also local to me in Portland, Maine), Running Tide, shut down.

On the other hand… These kinds of challenges are not unique to carbon removal, or to DAC specifically. Most of the reasons Orca fell short of its design targets are pretty classic First-of-a-Kind problems for new types of industrial facilities. In fact, I think the story here is not so much that DAC is hard, which everybody already knew, but that the real world is hard. For example, in the real world, in Iceland, where Orca was built, winter is hard.

This is why learning curves are so important. “Aha” moments are wonderful, but most progress comes from people trying something, taking stock of what worked and what didn’t work, and then trying again. In fact, Climeworks appears to have learned a lot during just two years of operating Orca. Here’s some more data:

Speaking of learning, lots of people are currently obsessed with machine learning and looking for useful things to do with Generative AI. Count me among the skeptics that GenAI is the next “industrial revolution” (the fourth? fifth? which industrial revolution are we on?) But one application for which I’m pretty excited about these types of models is scientific discovery. GenAI seems especially promising for identifying “candidate” materials which are likely to exhibit specific performance parameters. In the field of DAC, this approach already appears to be leading to better sorbents for CO2 capture. Here’s one last chart, from a paper recently published in Nature, illustrating how AI was used to hone in on two metal organic framework (MOF) structures which were then confirmed to capture CO2 more efficiently than established sorbents. The technology developer Svante is apparently already moving to commercialize one of these materials.