How will we keep warm in the winter?

The ten biggest questions in energy & climate tech, Question 6

Current hypothesis: With heat pumps. (mostly)

I need to admit… I’ve fallen for heat pumps. I think I’m in love.

Naturally I want you to love them, too. So, I’m going to tell you a whole lot about them - probably more than you want to know. But I feel strongly that this can’t be a passing infatuation. To truly adore the humble heat pump, you’re going to need take all the right steps to enter into a relationship.

First, you need to understand heat pumps; then you need to get to know all of their shortcomings, and accept them for what they are; then you need to recognize that there’s no other heating solution you’d rather be with to decarbonize space heating & hot water. And then, finally, you can begin to work on personal growth, and acknowledge that you’re probably going to need to build multiple relationships along the path to affordable, reliable, zero-carbon heat.

The magic & mundanity of the heat pump

Humans are prima donnas about temperature. We like to live within fairly narrow ranges, hanging out in 70-75 degree spaces, and bathing in 80-100 degree showers.1

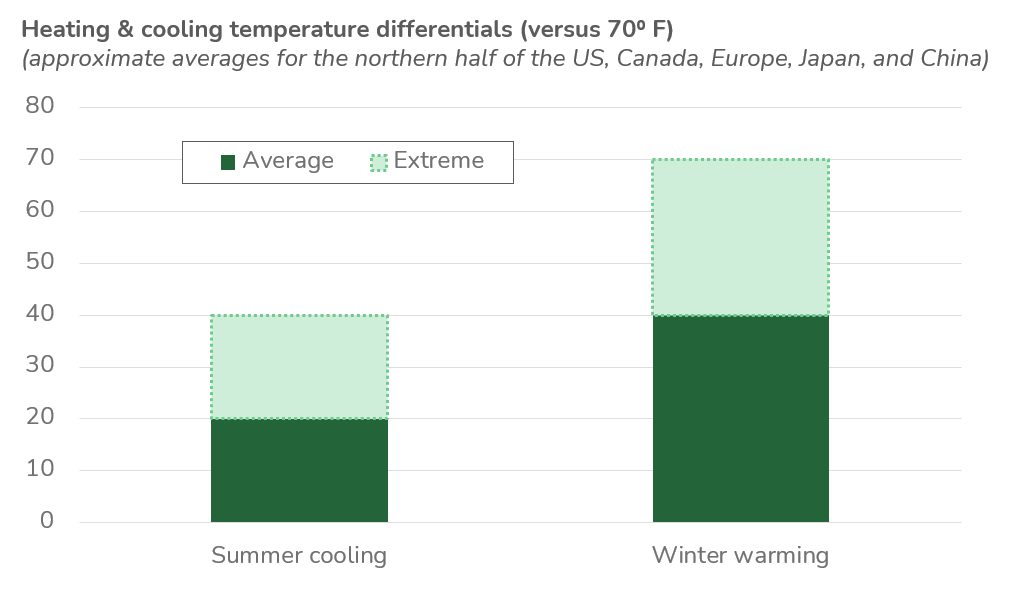

Maintaining these goldilocks temperature zones takes a lot of work, both to heat and to cool the spaces we live in. But, despite the world getting warmer, heating is probably going to be the bigger problem for most of the “global north”, for two reasons:

Heating consumes more energy. Today, about 4% of primary energy consumed in America, for example, is used for space cooling, while 13% is used for space & water heating. That’s largely because, for the majority of us who live in temperate climate zones, it’s really just a little hotter than we’d like in the summer, but it’s a lot colder than we’d like in the winter. The difference between peak heating & peak cooling needs is even more extreme.

Nearly 100% of energy for cooling already comes from electricity, while about 85% of energy for heating comes from the direct, on-site combustion of fossil fuel (in the US). This means that cooling is already well positioned to be decarbonized by clean electrons produced by renewables, nuclear, and other forms of zero-carbon power generation. Heating is not.

Why this discrepancy between how we heat and how we cool? Essentially, because burning stuff for heating is relatively easy to do, while burning stuff for cooling is not. For most of human history, all the stuff we had to burn was wood and animal dung, so gathering heating fuel was a huge pain. But since we discovered fossil fuel, heating has been a snap.

Of course, burning vast amounts of fossil fuel is no longer a viable strategy for heating. So, how will we keep warm in winter? The answer is that we’re going to have to do a lot more heating in the same way we do cooling.

Cooling is a tricky technical problem. Handheld fans and buckets of cold water can help, but in the parlance of venture capital, “they don’t scale”. In order to really cool a space down, you need to sap some of the heat energy out of it, and dump that heat elsewhere.

[High school physics reminder: the universe likes heat energy to be evenly distributed, everywhere. So, moving heat ‘uphill’ temperature-wise tends to entail working against the universe’s vision, and therefore consumes energy.]

Today, we accomplish this goal with a technology that is simultaneously so mundane that most people have never thought about how it works, and so magical that I still sometimes find it hard to believe it works at all. This technology is the humble electric air-source heat pump. (There are other important types of heat pumps, which I’ll discuss in a bit, but from here on out I’ll just use “heat pump” to refer to the electric air-source category)

Heat pumps are one of the most important building blocks of the modern world. You probably have at least three in your home (refrigerator, freezer, & air conditioner) and one in each car.

The vast majority of all heat pumps run on what’s called a “vapor compression cycle”. They employ a type of gas called a “refrigerant”, of which there are dozens of varieties, and whose properties are responsible for the apparent magic of the system. Refrigerants flow through a loop running from a heat “source” to a heat “sink” (e.g. the inside of your refrigerator to the outside). At the source, the refrigerant is allowed to expand (and in most cases evaporate), which absorbs heat; at the sink, the refrigerant is compressed (and in most cases condensed), which releases that heat. And on and on they go.

Herein lies the magic: this cycle can pick up and deliver way more heat energy than it consumes in electrical energy. For one joule of electricity, a completely ordinary heat pump might be able to move three joules worth of heat. This is, by far, the closest thing to a free lunch that we get in the energy system. (The average ratio of joules moved to joules consumed is referred to as a “coefficient of performance”, or COP. In the example above, COP = 3.)

It’s always been possible to run a heat pump in the opposite direction, in order to heat a space up in the same way that we cool it down. Remember once more from high school that there’s plenty of heat energy in the air even when it feels very cold to we, humans. The fact that we feel so chilled below about 50 degrees Fahrenheit is an artifact of our biology, not thermodynamics. There’s heat energy in the atmosphere down to absolute zero, which is negative 460 degrees Fahrenheit! Hence, the coldest winter temperatures for us are relatively balmy in the scheme of the universe, with plenty of heat energy available in the air that we can hypothetically pump into our homes and hot water tanks.

So…why don’t we already use heat pumps for heating?

Why don’t we use heat pumps for heating?

Actually, we do! Just not very much (yet). Unfortunately, the reasons are plentiful. Here’s a list of the biggest issues you’re going to need to accept, if you’re going to begin a long-term, decarbonization-focused relationship with heat pumps.

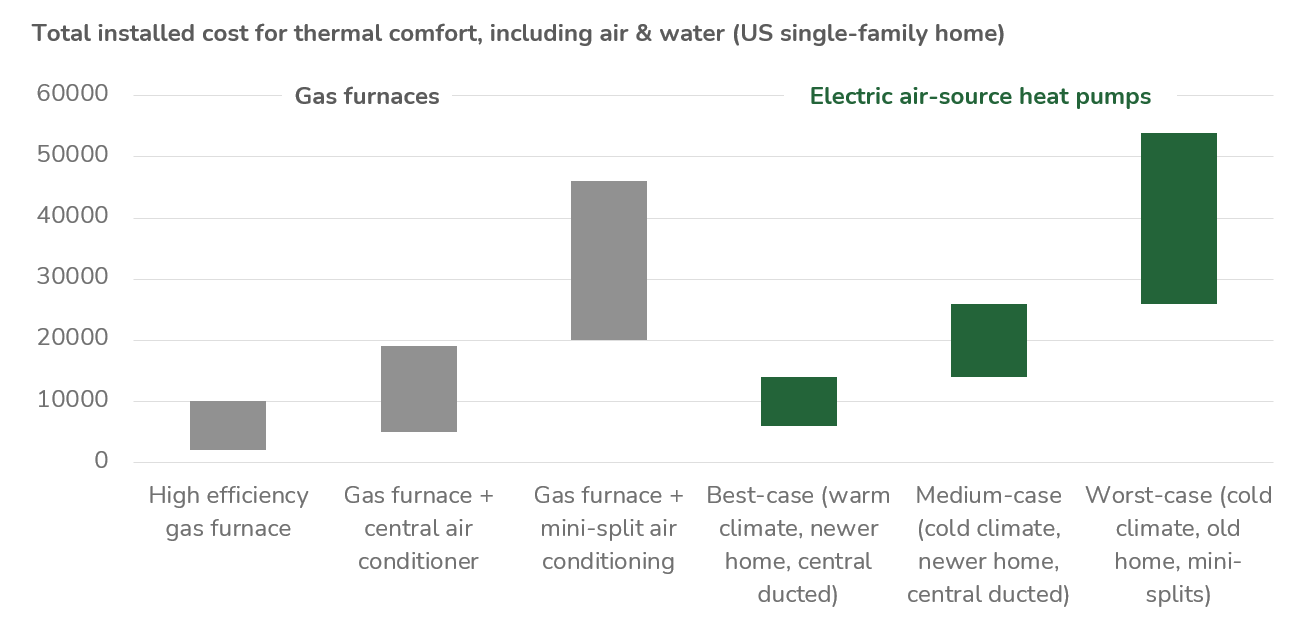

Natural gas heating systems tend to cost less than heat pumps, especially for older homes. (That said, there’s a lot of nuance in up-front cost comparisons, which I’ll discuss below.)

The whole process for buying & installing heat pumps is kind of a mess; plus, heat pumps still come with some minor trade-offs when it comes to aesthetics and comfort.

In North America, gas-based heating systems are cheaper to run than heat pumps, because the price of gas is so much lower than the price of electricity.

Deployed at scale, there’s a serious risk that heat pumps put a massive strain on the electrical grid, from power generation, to transmission & distribution.

Heat pumps technology is, somewhat ironically, at risk from climate regulation. It turns out that those magic refrigerant gasses used in nearly all heat pumps today also happen to be extremely potent GHGs, with hundreds to thousands of times more global warming potential than CO2.

I’m going to discuss each of these issues in turn, beginning with heat pump economics.

First: up-front cost.

Simple comparisons between heat pumps and alternatives are hard to make. For the majority of consumers, natural gas furnaces & boilers are the incumbent solutions to beat; and compared with a gas heating system alone, heat pumps for both space and water heating are almost always going to be at least a bit more expensive.2

In some cases, they’re waaaaay more expensive. For example, many older buildings utilize pipes filled with hot water or steam to distribute heat into each room. These systems are referred to as “hydronic”. It’s hard for heat pumps to integrate with hydronic systems because it takes a lot more work to reach hot enough temperatures.3 Today, the best option for heat pumps in most of these homes are called “mini-split” systems, in which each distinct space gets its own indoor heat pump “head”. Each head needs to be connected to an outdoor compressor unit via refrigerant lines, which often need to snake up the side of a home. For these types of systems, both the cost of basic equipment and labor can add up very quickly. Plus, these things look kinda weird. (See photo below.) On the other hand, they offer room-by-room temperature control, which is a really appealing and often energy-saving feature.

On the other hand, when you install a heat pump for heating, you’re getting a two-for-one deal, because any heat pump you buy for heating purposes these days is going to be bidirectional, meaning that it will also provide air conditioning.4 So, if you don’t already have air conditioning, and you want it, then you might as well pay a little extra for a heat pump that can also do some heating. If you already have air conditioning, then the economics get trickier, as the timing of when you need a new heating system and when you need to replace your central AC are unlikely to be perfectly aligned.

There’s all kinds of other nuances to consider for each individual building: the size of its ducts, if it has them; the location of its water pipes, which could freeze if they’re not well heated in the depths of winter; the space to put outdoor compressor units; and the list goes on.

Stepping back, at a macro level, my conclusions are:

Up-front cost is not going to be the primary constraint on heat pump deployment for the majority of buildings. In particular, as more building owners decide to add air conditioning, or need to replace their old AC units, adoption of heat pumps for heating should be a relatively low-cost, low-friction endeavor.

However, up-front cost is likely to be a pretty daunting hurdle in a bunch of important sub-categories of buildings. For example, cold climate buildings with old, hydronic heating systems; and really tall buildings in dense cities which might not have sufficient space for large outdoor heat pump units, or big enough ducts for peak heat delivery.

And yet, beyond up-front cost, I still see several other stumbling blocks for consumers taking their first look at heat pumps…

We need to talk about “softer” side of heat pumps: product design; consumer education, marketing, and sales; and the user experience.

I’ll start by sharing a personal story.

I live in one of those older homes with a hydronic heating system (forced hot water, fueled by an oil furnace), in a relatively cold climate: South Portland, Maine. My home doesn’t have air conditioning, but I’d like it to, as the climate is getting hotter.

This summer, I’ve already had three HVAC contractors walk through my home to provide quotes for mini-split heat pumps. The first contractor was very knowledgeable and friendly, took his time, and asked good questions. However, his estimate was about 50% higher than I was anticipating based on reputable sources like EnergySage, as well as what I’ve heard from local friends and neighbors. He also told me that due to liability concerns, his company would not install heat pumps as the sole heating system for a home. So, I’d also need to replace my aging furnace for backup heat.

From the get-go, the second contractor seemed intent on selling me against heat pumps. He told me that they would be extremely expensive to install, although his estimate came in significantly lower than the first. He told me that the price of oil would probably “go way back down again once we have a new president”. (That was a surprise, as I suspect I exude “raging moderate democrat” from every pore.) And he told me that the warm air blown out of a heat pump would feel less comfortable than heat emanating from cast iron radiators. (That might actually be true, and is a common knock on heat pumps.)

Anecdotally, I’ve heard over & over that this kind of heat pump skepticism is endemic among local contractors.

Meanwhile, the most that I heard about heat pump aesthetics from either of these contractors was a joke that my color options were “white, or white”. Neither contractor mentioned where the refrigerant lines would need to be bolted to the outside of my home. Neither brought up how my family would control our heat pumps, or how those controls might be integrated with the thermostat for our oil furnace…which they both recommended I keep in place for the coldest days of the year.

Thank goodness, the third contractor I called was a gem. (If you live in Maine, I highly recommend Royal River Heat Pumps for a consultation.) His depth of experience was obvious; he talked me through all of the little details; he explained the pros & cons of each decision; and he’s not trying to gouge me.

So, I think this is going to work out for my family. But I must say that the overall experience was frustrating, and could easily have ended after two contractor visits. Simply replacing my furnace would have been a lot cheaper & easier!

And this is the experience of someone who’s an expert on the energy system, and who’s actively pursuing heat pumps. I’m a heat pump salesman’s dream.

The majority of consumers are not. They probably haven’t thought whatsoever about heat pumps, because they haven’t thought about their heating system, period. About 80% of home heating systems are purchased & installed in distress when an old furnace breaks down. As you can imagine, those consumers tend to go with the cheapest option that can be installed before their pipes freeze, which is always going to be a new furnace or boiler.

Hence, I’ve come to believe that there’s a big opportunity for businesses to focus on all of the “soft” barriers to heat pump adoption. A few examples from the startup ecosystem are BlocPower, Quilt, Conduit Tech, and Amply, which are each taking somewhat different approaches to making heat pump adoption cheaper, easier, and perhaps even…sexier? I still have no idea whether it will be possible to build a Tesla-esque brand, or a Sunrun-esque sales motion for heat pumps, but I’m excited to finally see some experimentation in these areas.

Back to “hard” barriers: We need to talk about efficiency.

The amount of energy that a heat pump needs in order to do its job is in large part a function of the difference in temperature between its heat source and sink. This temperature difference is referred to as a “lift”.

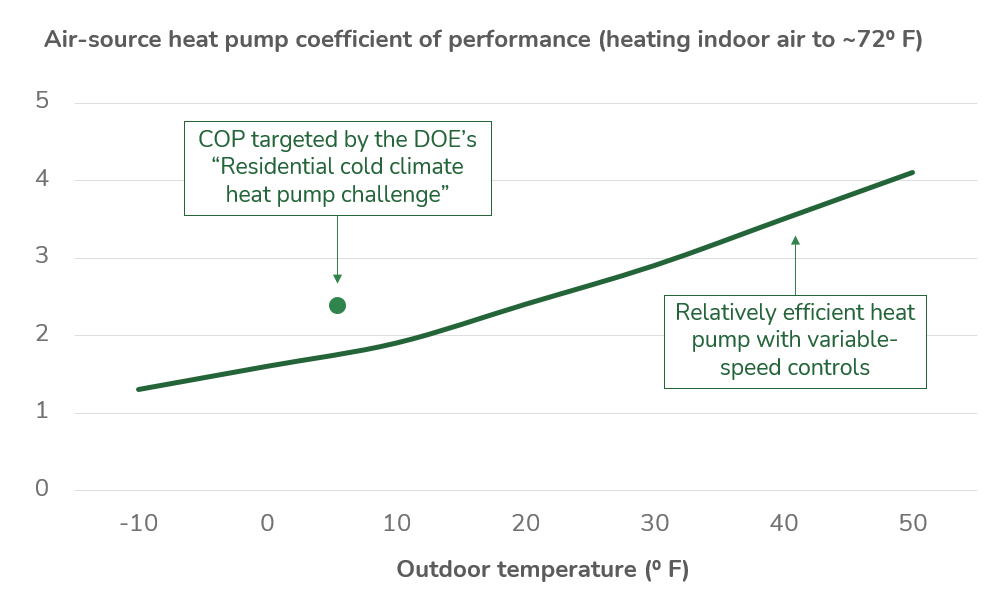

Analysis of heat pump peformance by the National Renewable Energy Laboratory, or NREL, illustrates the impact of temperature lift on a heat pump’s efficiency, which you’ll recall is typically expressed as a “coefficient of performance” (or COP). NREL derived the following relationship based on test data from a heat pump considered to be relatively efficient in cold climates, in 2022.5

Absolute best-in-class heat pumps today might do a little better than the curve represented above. For example, the US Department of Energy has issued a challenge to heat pump manufacturers to improve cold climate performance, and several major global heat pump manufacturers have already announced that they’ve hit the DOE’s targets. However, the relatively low efficiency of heat pumps in colder temperatures remains problematic for a few big reasons.

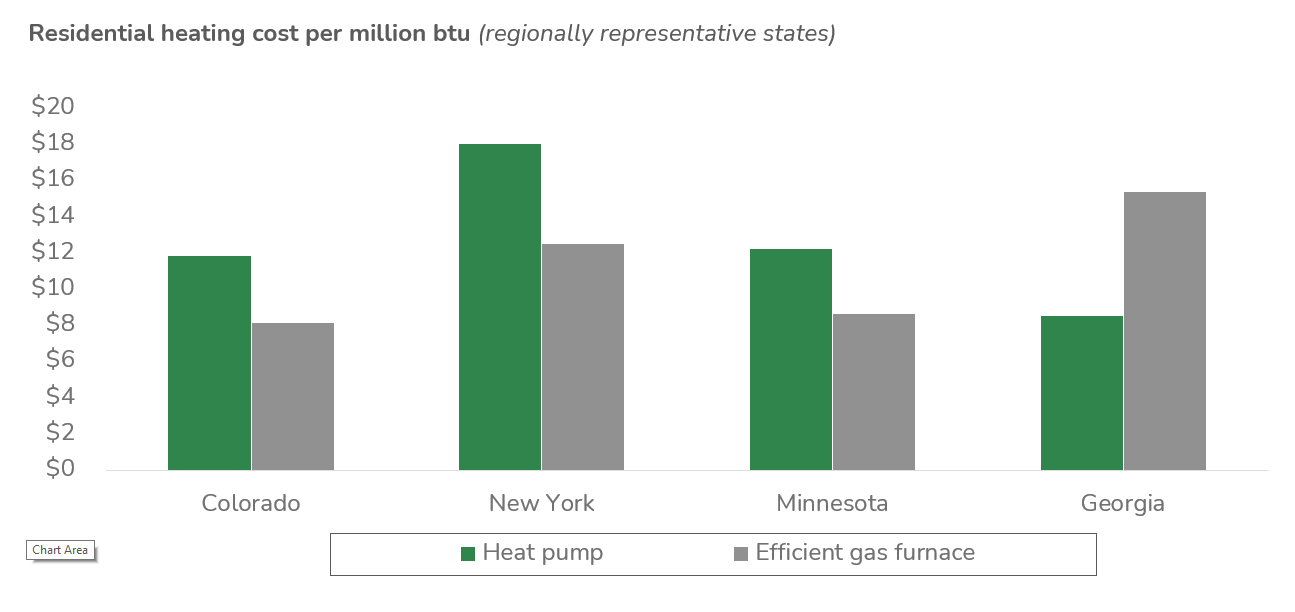

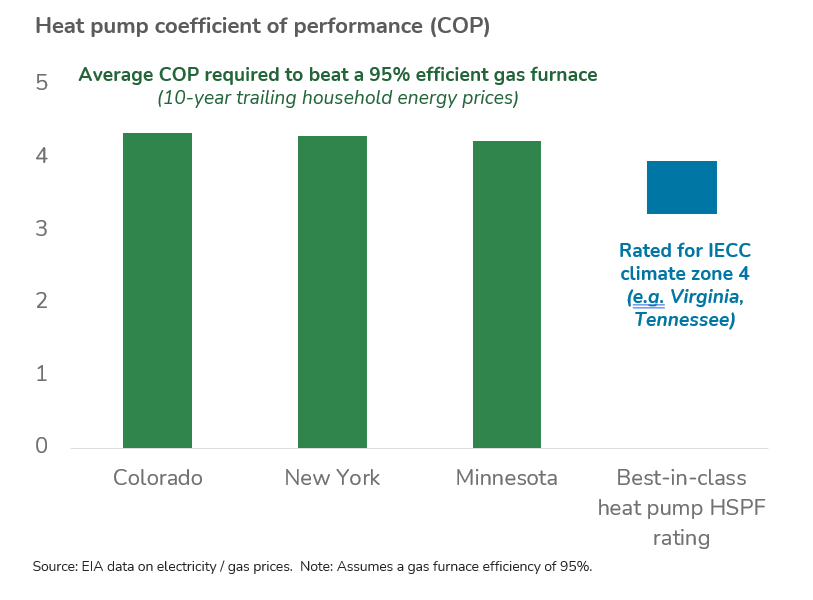

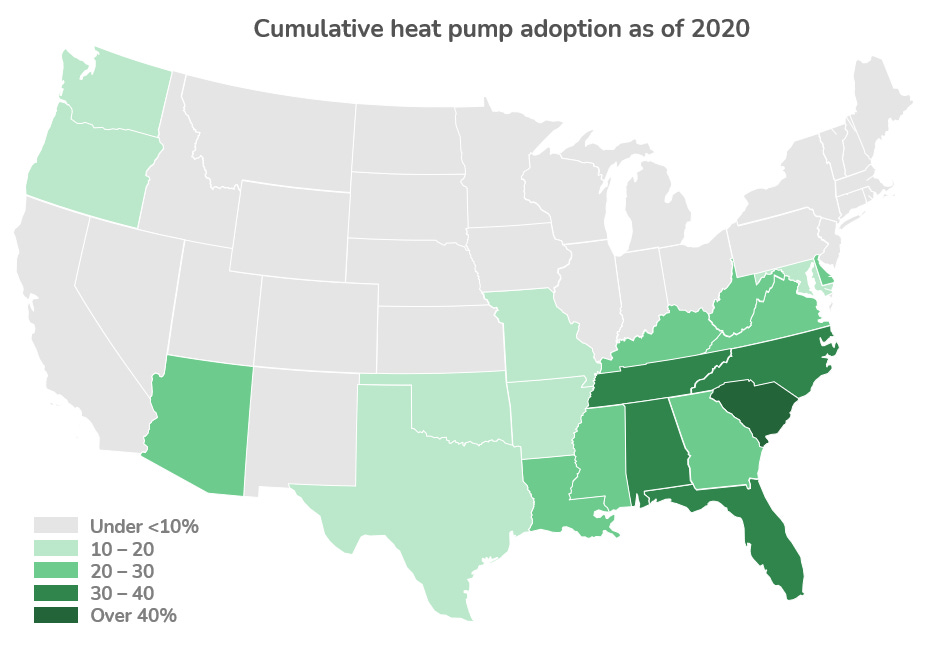

The first reason is kitchen table economics. A lower COP translates directly to a higher cost of energy. In North America, which has some of the world’s lowest natural gas prices, heat pumps need an especially high COP in order to beat the operating cost of an efficient natural gas furnace. Take a look at three of the biggest, regionally representative cold climate states: New York, Colorado, and Minnesota. For the past decade, across those three states, the magic number for residential heat pump COP has been a little over four. That’s higher than today’s top-shelf heat pumps are rated to achieve, even towards the southern periphery of temperate climate zones.

It’s very difficult to track down reliable data on real-world COPs for the latest generation of cold climate heat pumps. But, given some estimates on the optimistic side of reasonable, heat pumps would cost significantly more to run than a gas furnace in all three of the aforementioned cold climate states.

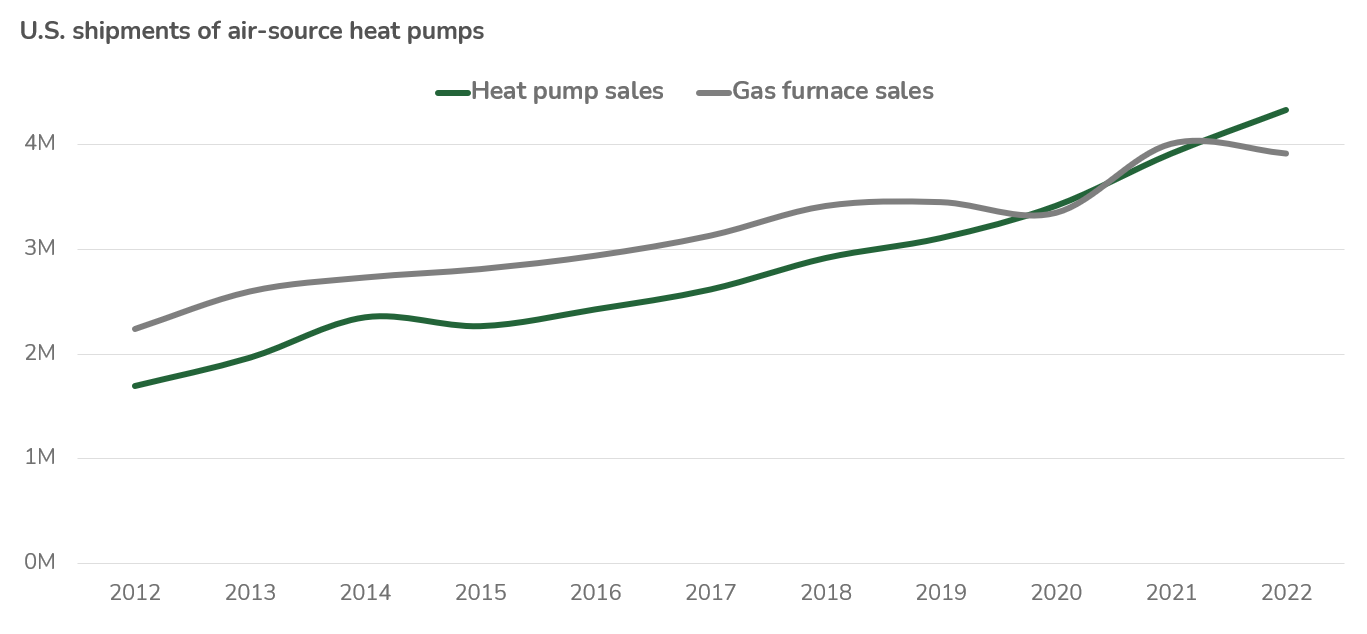

One glance at the chart above, however, and it’s no surprise that heat pumps have begun to gain a lot more traction in sub-tropical climates: relatively warm places that only need a little bit of winter heating. In the US market, heat pumps have been doing especially well in the humid Southeast, where efficient air conditioning is also prized. In states like Georgia, heat pumps have become the heating system of choice for nearly two thirds of new homes. Because of this trend, and because such a large share of new home construction in the country is taking place in the “sun belt”, heat pumps outcompeted gas furnaces nationwide, for the first time, in 2022.

But, don’t let this macro coup for heat pumps lull you into a false sense of complacency. Heat pumps are still struggling mightily north of the Mason-Dixon line. Even for new homes, which are much easier to satisfy with heat pumps than retrofits, heat pump adoption remains at just 10% in the Northeast & Midwest, and about 25% in the West. These tend to be the places in which heat pumps simply cost more to run than natural gas.

The hardest “hard” barrier for heat pumps has yet to come.

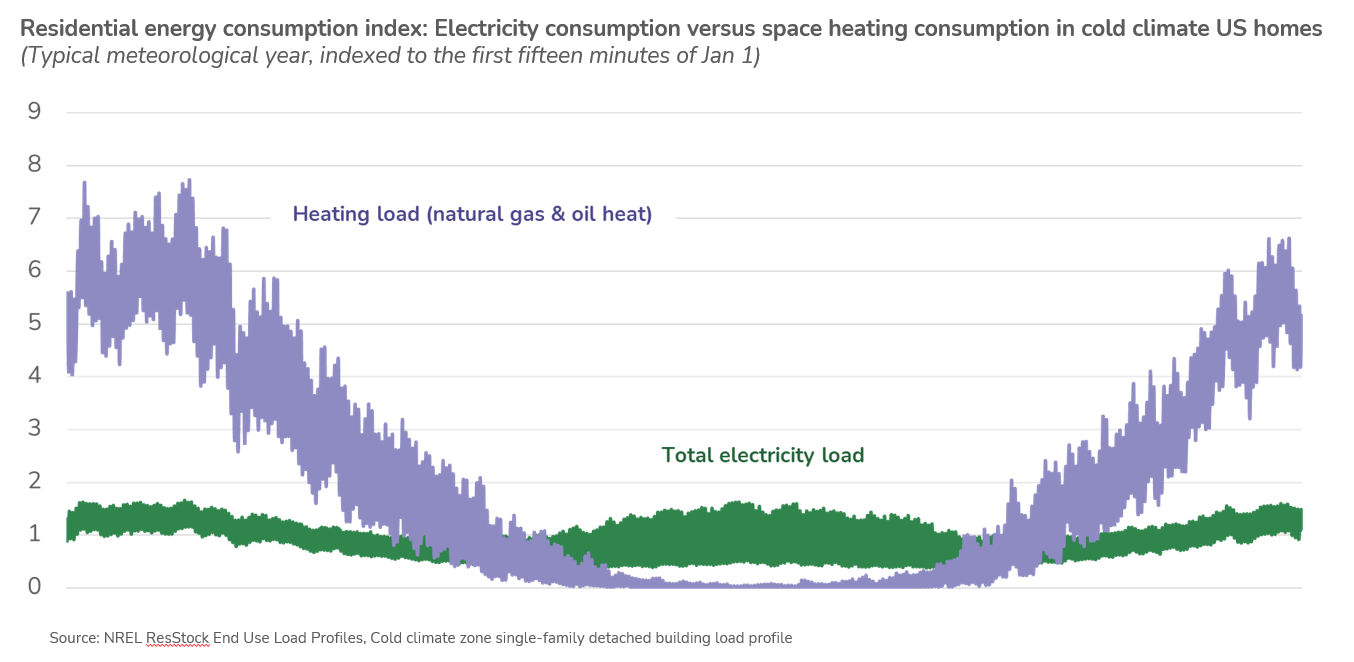

In colder climates, not only do we use a lot of energy for heating; we use the majority of it during just a third of the year. In energy system parlance, demand for heating is super “peaky”. In fact, it’s much peakier than current electricity demand.

Because of heat pumps’ magical efficiency, they ought to be able to reduce aggregate demand throughout the heating season by about two thirds. But their ability to reduce peak energy demand is much lower, because their efficiency bottoms out when it’s coldest outside…which is when we need heat the most.

Roughly speaking, today’s cold climate heat pumps consume 50% more energy when it’s 10 degrees outside than when it’s 30 degrees outside. During occasional cold snaps below zero, heat pumps just barely outperform resistance heaters. They practically turn into toasters.

Consequently, on the coldest winter nights, adding heat pumps to a typical single-family home is like adding TWO electric vehicles plugged into Level 2 chargers. If the energy transition goes according to plan, this will be in addition to one or two actual EVs, which might simultaneously be plugged in.

Hence, at a macro level, widespread heat pump deployment could quickly become the dominant driver of peak electricity demand. Winter nights would put a tremendous strain on every aspect of the power grid, from generation capacity to service transformers. An excellent analysis of my home state of Maine showed that fully electrifying heat would increase peak electricity demand by about 1.5 times, independent of new electricity demand from vehicles & industry.

There are big implications for the cost of electricity, and frankly, those implications aren’t very well understood, because they’re extremely difficult to model.6 What we know for sure is that the cost of serving this peaky new demand will need to be paid for, somehow, by energy consumers (for example, in the form of peak-coincident demand charges). And rising electricity costs will make the kitchen table economics of heat pumps more daunting for consumers.

One more hard challenge: About those “magical” refrigerants…

Remember the ozone layer?

Back in the 1980s, scientists identified a big threat to the ozone layer, which was the emission of chlorofluorocarbons, or CFCs. Among other uses, CFCs were the original class of heat pump refrigerants. Fortunately, the nations of the world got together and agreed on the Montreal Protocol to phase out CFCs. And then, by golly, we actually went ahead and implemented it! The Montreal Protocol has since become a case study for international environmental cooperation.

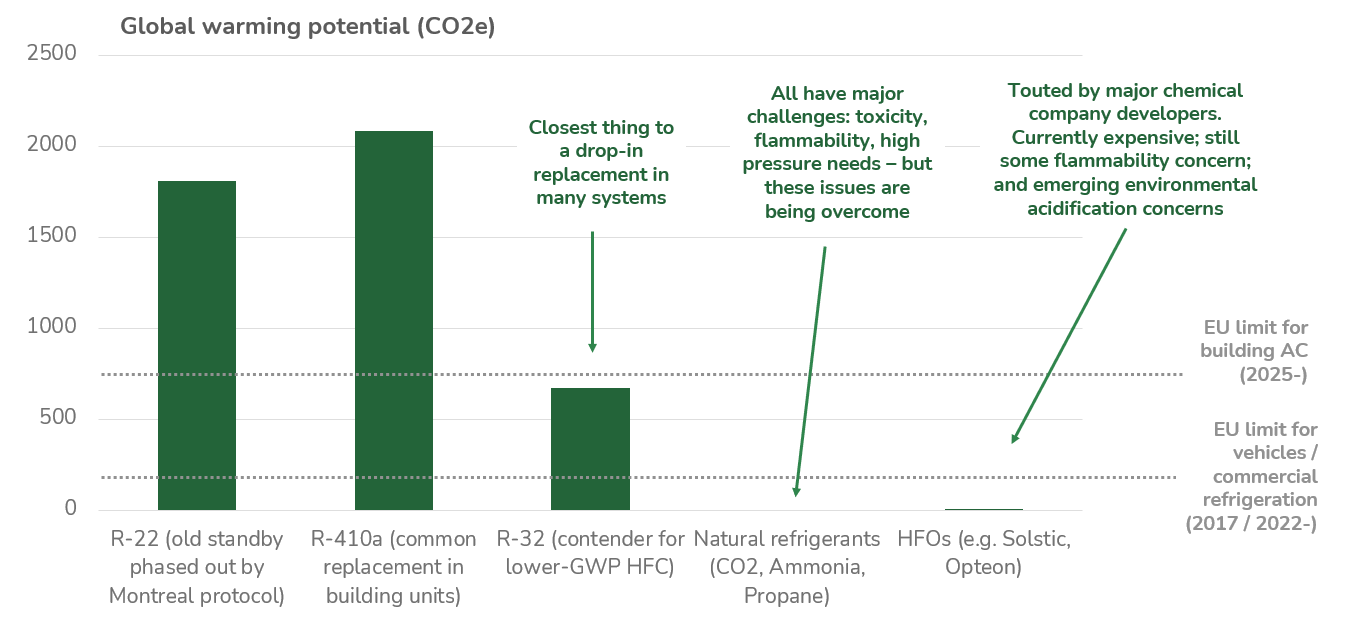

The HVAC industry managed to address its CFC problem by transitioning to different class of refrigerants called hydroflourocarbons, or HFCs. But, it turns out that both CFCs and HFCs share another problem, which is that they’re both extremely potent greenhouse gases…with around two thousand times as much global warming potential per molecule as CO2. HFCs actually tend to be a little worse than CFCs from a climate standpoint.

It also turns out that HFCs tend to leak. They do so throughout a heat pump’s life cycle: from manufacturing, through operations, and at the end of life when old units are carelessly discarded. A 2017 study of household air conditioning systems showed that as much as 30% of their total life cycle climate impact can be attributed to these leaks! (That share can be even higher for certain refrigeration product categories.)

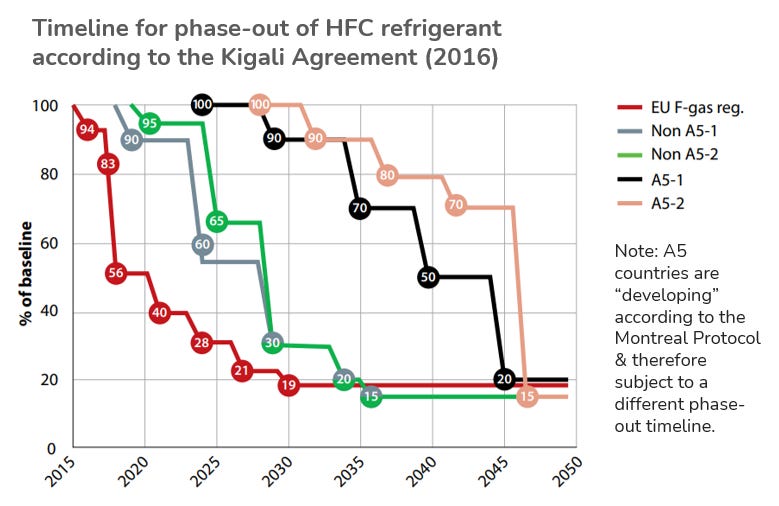

So, we amended the Montreal Protocol. In 2016, most nations signed on to the Kigali Agreement, which lays out a specific timeline for countries at varying stages of ‘development’ to phase out HFCs, too.

Now we find ourselves in a pickle. Following the original Montreal agreement, phasing out CFCs ended up being relatively painless for manufacturers, because HFCs turned out to be a nearly perfect substitute. But HFCs have no such obvious successor.

The closest we have to a drop-in replacement for the most common HFCs is simply a different HFC, referred to as R-32. But the global warming potential of R-32 is still pretty high: about a third of the status quo. Instead, we might turn to a number of so-called “natural” refrigerants, such as carbon dioxide, ammonia, and propane; but each of these options has a number of well established technical & safety limitations. And finally, there’s a relatively new class of alternatives being touted by major global chemical companies, called hydrofluoro-olefins, or HFOs. HFOs have extremely low global warming potential, but they’re bedeviled by toxicity concerns. Many HFOs degrade in the atmosphere into an environmentally persistent type of acid. Most importantly, though, HFOs are at risk of being heavily restricted or banned by regulations targeting a broader class of chemicals called PFAS…often referred to as “forever chemicals”. Debate over PFAS regulations is intensifying in Europe as I type.

The take-away is that refrigerant emissions complicate heat pumps’ ability to serve as a fully zero-carbon solution. I’m confident that heat pumps’ energy consumption emissions can be dramatically reduced by decarbonizing electricity supply, but it’s not clear today how we’ll ever fully deal with the refrigerant emissions problem.

Remember, I actually want you to love heat pumps

I know, I know. I just deluged you with over 2,500 words disparaging heat pumps. I had to get that out of the way.

Like I said at the outset, that’s because I friggin’ LOVE heat pumps, and I want you to love them just the same, which means doing so with eyes wide open to all of their downsides. That’s how true love works.

Here are the two biggest reasons I’ve fallen for heat pumps, despite their many shortcomings:

Our other options for decarbonizing heat are all, for various reasons, way worse, or insufficient for this enormous task. Hence, I think it will be exceedingly difficult to fully decarbonize most buildings without heat pumps.

All of those 2,500 words of caution were focused somewhat narrowly on the air-source electric heat pump. There are a number of other types of heat pump which can help shore up the leading category’s weaknesses; and a slew of emerging technologies which might completely change the paradigm.

First, let me tell you why some of the other potential approaches to decarbonizing heat won’t work as well as heat pumps. In short, none of these options are sufficiently scalable. (Note: discussing each of these pathways could consume a whole essay, so please pardon my brevity. I may go into more depth on these topics in future posts.)

Carbon capture & removal: Capture technology works best at industrial scale, and is unlikely to ‘scale down’ all that well. More critically, building the infrastructure required to transport CO2 from billions of individual buildings to remote sequestration sites is so impractical as to be laughable. Perhaps there will be a small number of buildings, located in close proximity to high-value CO2 utilization opportunities, for which this makes sense. This may be a niche that’s big enough to sustain a successful business, but it’s not going to move the needle on global emissions.

Hydrogen: There are still some dreamers out there who believe we’ll be able to transition existing natural gas distribution systems to deliver hydrogen instead of methane. It’s true that in places where gas pipes are already made of thick plastic, we could probably prepare those pipes to make this kind of transition at moderate cost. It’s also possible to build household & commercial boilers that can run on hydrogen. But…making this transition safely would require extraordinarily close coordination with all of the consumers whose household appliances need to be ready to burn hydrogen. Blending more than about 7% hydrogen by energy content into a gas network puts every consumer of gas from that network at risk, if they’re not fully prepared. The only way that I can see this being done is with an extremely heavy policy hand. Every level of government will need to be involved. Frankly, I’m just extremely skeptical that the public will tolerate this kind of intervention outside of a handful of jurisdictions. And even in those places where the public might be rallied behind such a plan, the economics of distributed hydrogen delivery tend to look even worse than the economics of electrification. Hence, while I see some potential for very low levels of hydrogen blending into natural gas systems, I believe hydrogen will be, at best, a small part of the solution.

Renewable natural gas: The most common sources of RNG today are landfills, cows, and pigs. These are good sources of biogenic methane that would otherwise be emitted into the atmosphere. My view is that we should be urgently moving to capture as much as that methane as possible to reduce the carbon intensity of pipeline gas. But there are only so many landfills, cows, and pigs; and gasification of any other kind of biomass gets a lot more complicated and expensive. (Also, there are other competing uses for that biomass, which I’ll discuss in Question 8: What’s the best use of our waste biomass?.) None of this stuff is available in sufficient quantities to address the majority of heating demand. My bet is that “biogas” from any source will end up being a bigger contributor than hydrogen, but will ultimately end up in a “best supporting player” role.

Loving heat pumps means embracing their diversity

As I mentioned above, air-source electric heat pumps are by far the most widely deployed form of heat pump today, but they’re not the only game in town. Let me tell you about two other types of heat pump, neither of which is likely to address the entire heating market, but both of which could lay claim to major building segments.

Let’s start with ground-source electric heat pumps (often referred to as “geothermal” heat pumps). As their name implies, ground-source heat pumps tap into the ground as a source of heat. They also use the ground as a place to dump heat during the summer. (But calling them “ground-source-and-sink heat pumps” is too awkward.)

The ground is superior to the air for heat pumping purposes because it can hold such vast quantities of heat. One can pump a lot of heat either into or out of the ground without making a big impact on the temperature of the surrounding earth. In fact, a ground-source system can also act as a form of seasonal energy storage, burying heat during the summer which can subsequently be retrieved during the winter. A system can be designed such that it’s consistently exchanging heat with the ground at temperatures in the ballpark of about 55 degrees.

The benefit of using the ground in this way is that it dramatically reduces the “lift” that’s required from a heat pump in both heating & cooling mode. Actually, in the summer these heat pumps are simply enabling heat to flow in the direction it wants to flow, from a warmer source to a cooler sink. Hence, ground-source heat pumps are more efficient all year round, and they can almost entirely avoid the kind of peak demand spikes which are most concerning for the electricity grid.

In short: they’re probably the most efficient combined approach to heating & cooling that we’re going to get.

So, there must be a catch…

…and there is one, of course. There are two related reasons that ground-source heat pumps still only account for about 1% of all heat pump installations. 1) They’re expensive, and 2) They’re disruptive to install.

Air-source heat pumps are pretty compact systems. Using small fans, they can easily exchange heat with plenty of outdoor air to keep a house comfortable, in the space of a box about the size of a suitcase. Ground-source heat pumps, on the other hand, need to exchange heat with a lot of earth, and only way to do that… is to exchange heat with a lot of earth. This entails putting a whole bunch of fluid filled pipes underground, which requires some combination of digging and drilling. Your basic options are:

Go wide, and lay big loops of pipe horizontally, about 5-10 feet deep. In this case, you’re probably digging up a plot of land roughly equal to the size of the building you want to heat and cool.

Go deep, and install your pipes vertically to reach hundreds of feet below-ground. This strategy doesn’t require as much surface area, but it calls for heavier and much more expensive drilling equipment.

So, the installation process is daunting; so far, too daunting for the category to gain any real momentum.

And yet, I sense we may be on the cusp of an inflection point for ground-source heat pumps. Frankly, I think we need to be. For some types of buildings, the year-round efficiency of ground-source heat pumps is really the only path I can envision to cost-effective decarbonization.

Plus, we’re seeing some promising new approaches make their way into the market. Most of these innovative solutions are targeting larger buildings, and aim to make installation less daunting. For example: Bedrock is developing tools to drill deep boreholes faster & cheaper. Darcy and Celsius have each developed (very different) solutions which are each capable of substantially reducing the number of boreholes that need to be drilled. Brightcore is even demonstrating the ability to drill deep boreholes from inside a building!

In my view, economies of scale tend to make large buildings the best targets for ground-source solutions, but it’s too early to count out single-family homes. Dandelion has now spent years honing the process to deploy ground-source heat pumps for individual households. And a handful of natural gas utilities are beginning to pilot ‘district’ ground-source projects, in which the utility owns & operates all of the underground elements of a ground-source system to serve an entire neighborhood.

Next, let’s talk about thermally-driven heat pumps.

The vast majority of heat pumps are electrically-driven, but they don’t have to be. It’s also possible to run a heat pump cycle with thermal energy - i.e. by burning fuel.

Thermal heat pumps are not an entirely new concept, but historically they’ve only been commercialized, with limited success, in a few niche segments. My firm, EIP, has invested in a company that’s aiming to breathe new life into the product category by bringing a thermal heat pump to the residential market. That company is SMTI.7

Stepping back, there are five primary advantages one can gain by running a heat pump on combustion, rather than an electrically driven compressor.

First, in many places, fuel is much cheaper than electricity. On average in the US, the price of natural gas is about a quarter of the price of electricity delivered to households. You’ll recall, this is the reason that heat pumps are generally a poor financial investment for consumers in most cold climate states (not to mention, Canadian provinces).

Second, the efficiency of thermal heat pumps is less sensitive to outdoor temperatures than electric heat pumps. Because thermal heat pumps are always generating some of their own heat, through combustion, they can operate down to extremely cold temperatures - well below the range of even the most robust electric heat pumps (which tend to bottom out around -15 degrees). Thermal heat pumps can also deliver heat at very high temperatures, consistent with hot water and older hydronic heat distribution systems.

Third, thermal heat pumps have zero impact on the electricity grid. As I discussed earlier, grid capacity could become a major constraint on electric heat pump deployment, especially in very cold climates.

Fourth, thermal heat pumps are easier to design for compatibility with natural refrigerants, most of which have zero global warming potential. SMTI’s thermal heat pump uses ammonia, thereby completely avoiding all of the Kigali amendment issues I discussed above.

Fifth, thermal heat pumps can be made relatively cheap & easy to install. SMTI’s product, for example, is pretty darn close to a conventional natural gas boiler in terms of cost and installation labor.

Of course, there’s always a catch…

…And for thermal heat pumps, it’s is an obvious one: they need to burn something. Today, that’s most likely going to be natural gas. In this way, thermal heat pumps are not yet a complete decarbonization solution. But then again, neither are electric heat pumps, as long as the grid is still at least a decade or two (or three, or four) from full decarbonization.

Hence, I think about thermal heat pumps as the most pragmatic solution for really cold climates today: an option worth investing in, which represents one of the biggest ‘bangs for your buck’ among building efficiency solutions. Even relative to an ultra-high-efficiency gas furnace, SMTI’s heat pump can reduce gas consumption and associated carbon emissions by about a third, beginning the moment it’s installed. In some cold climate zones, where the carbon intensity of the grid is still relatively high, a thermal heat pump will currently beat an electric heat pump on climate impact…especially when refrigerant emissions are taken into account.

But is it every going to be possible to fully decarbonize with thermal heat pumps? Probably not, although combined with other efficiency investments it’s possible to envision cutting natural gas demand by upwards of 75%. Such a large reduction in aggregate gas demand could enable scarce, zero-carbon gasesous fuels like RNG to play a much more meaningful role. This is a perfect example of how natural gas can serve as a backstop fuel, while natural gas infrastructure can support very high levels of decarbonization.

And anyway, purity tests are the bane of climate action. For all of the reasons I’ve laid out in this post, building heat is probably going to be one of the absolute toughest sectors of the economy to fully decarbonize, no matter what variety of heat pump we choose. All the atmosphere cares about is the total amount of carbon we emit, starting now. That’s why I believe thermal heat pumps can be such a valuable tool in our toolbelt.

All of the heat pump tools in our toolbelt

We’re going to need them all: a panoply of diverse heat pump solutions for different buildings, climates, and foundational energy infrastructure. Air-source, ground-source, thermal, hybrid… It’s time to get to know them all, and maybe fall in love?

Frankly, though, I’m not sure we can get this job done without adding some new tools to our belt. Building heat is an area in which I believe there’s room for a lot more innovation across the board, from business models to foundational technology. For example, I still believe there might be room for entirely new classes of heat pump (e.g. Blue Heart), which address the cold temperature and refrigerant limitations of established technology. I also really like the concept of hydronic solutions like Aris Hydronics with super low-cost thermal storage, like Harvest Thermal. As always, if you’re building something amazing in this space, please get in touch.

Oh and by the way: this post barely scratched the surface on cooling & refrigeration, two more topics that are intimately connected to the future of heat pumps.

And I almost forgot to mention my favorite heat pump company, EIP portfolio company AtmosZero, which is applying heat pump technology to industrial steam production! (See my prior post on industrial electrification for more context.)

You see, there’s always more to talk about with heat pumps. It’s heat pumps all the way down…

Enjoy this post? Please check out the rest of the Ten Biggest Questions in Energy & Climate Tech

My apologies to everyone else in the world besides Americans, but I am American, so I’m using Fahrenheit.

If you don’t add a heat pump for hot water, in addition to space heating, then you’ll still need a furnace.

There are a few air-to-water heat pumps designed to be paired with hydronic heat distribution, but even they don’t reach the temperatures that older hydronic systems require.

Suffice to say, my bet is that the number of households that will be willing to pay a high price for some air conditioning will increase pretty steadily in a warming world.

A five-ton Carrier Infinity Series heat pump with “Greenspeed” (variable-speed) controls.

Wonky energy economics sidenote: Most models attempting to quantify the cost of large-scale electrification employ a static cost estimate for transmission & distribution system upgrades (say, $100 per kW-year). In reality, however, the ‘supply curve’ for T&D capacity is unlikely to be flat. Instead, the marginal cost of adding more peak T&D capacity is likely to increase as peak load escalates to unforeseen heights, at a pace not experienced in decades. In my view, this is an area of especially high uncertainty within the domain of energy system modeling, and much depends on how well electric utilities plan & stage investments in infrastructure.

Technically, SMTI’s heat pump uses an “ammonia-water, single-effect gas absorption” cycle.

Canary just published data showing COPs fairly often stay well above 1.5 even down to sub zero temps. https://www.canarymedia.com/articles/heat-pumps/heat-pumps-outperform-boilers-and-furnaces-even-in-the-cold

Seems to me that the methane burning heat pump is fascinating, seems like it’s not the only solution you need though. If standard heat pumps can achieve a similar overall thermodynamic performance using grid energy, and assuming capacity will keep being added to the grid, then you may be at wash with a methane grid vs. methane heat pump. The difference is a methane grid can transition to more renewables over time but a methane heat pump can’t.