Is the future of low-carbon industry off grid?

Solar-powered data centers? Solar-powered industry!

Last December, a group of smart energy thinkers from Scale Microgrids, Paces AI, and Stripe published a thought-provoking white paper which begins with a few observations, and a question:1

Hyperscalers need enormous amounts of power ASAP to power AI data centers.

Procuring huge amounts of energy fast is a strategic imperative for hyperscalers and is of national security importance as well.

Grid expansion today in the US is slow.

Could off-grid solar microgrids in the US be big enough, fast enough, and cheap enough to be a compelling near-term alternative to building more natural gas power plants to meet near-term AI energy needs?

The title of the paper — “Fast, scalable, clean, and cheap enough”, doesn’t bury the lede: The answer is probably “yes”.

Say you want to build a 100 MW data center, and you want to build it fast. If you can hook it up to the electricity grid… great! But in many places, spare grid capacity is now extremely limited, and in some places there’s simply not enough to go around. The organization governing electric reliability in North America, NERC2, just published a new long-term reliability assessment, which shows that big swaths of the grid across the continent are struggling to keep up with demand growth — as evidenced by an elevated risk of shortfalls.

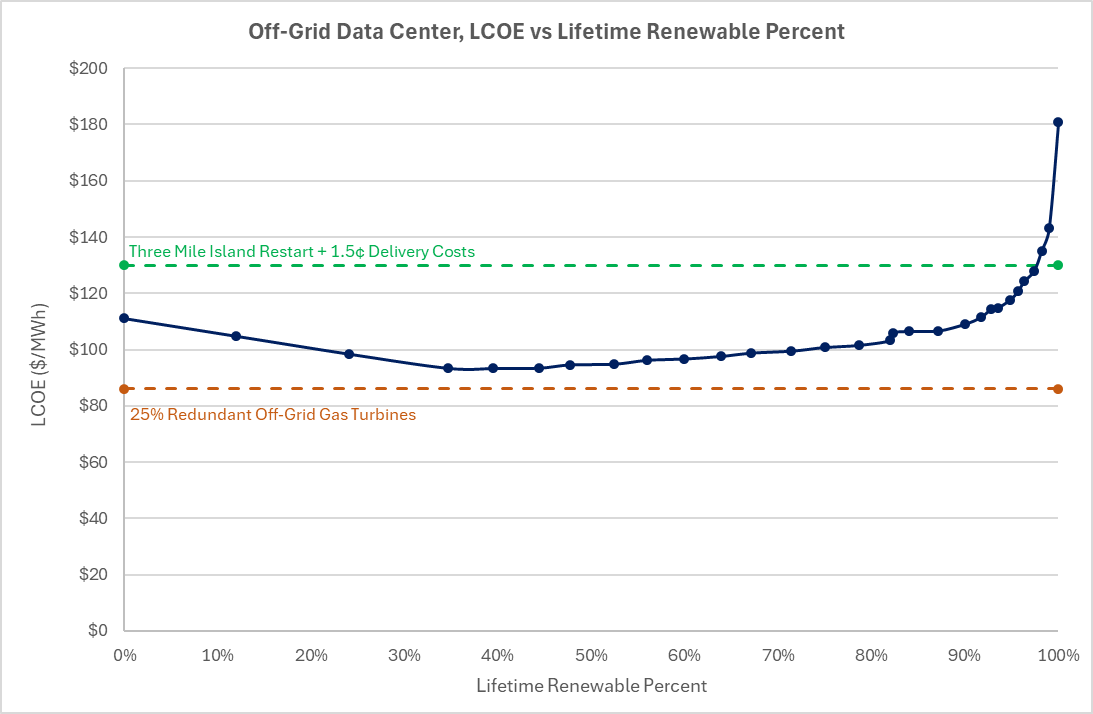

Okay, so maybe you decide to skip the grid connection. Another option is to quickly buy and install a bunch of relatively small, on-site gas turbines which can be run as an “island” without access to power from the grid (or perhaps with some access, but not firm access).3 The “Fast, Scalable, Etc.” team estimates that the levelized cost of energy (or LCOE) from this kind of setup would be around $86 per MWh, which is pretty darn close to the current US average price of $82 per MWh for industrial-scale grid power consumers.

[As an aside: A very large data center, on the order of 500 MW, could instead be powered by a single, large, combined cycle gas power plant, and almost surely achieve a much lower levelized cost of energy — on the order of $40-50 per MWh. However, a single large power plant is unable to provide the same ultra-high level of reliability as a fleet of smaller generators, for which individual outages or maintenance issues can be managed without unexpected downtime. So, if you decide to build a big CCGT, you’re also going to need to add the cost of a fleet of backup generators…]

But what if you care about carbon? (Even a little bit…) Well, if you can secure a site with strong solar resources in the US Southwest, and enough adjacent acreage to build a big-ass array of photovoltaic panels & lithium-ion batteries, this analysis shows that you could achieve practically the same price while sourcing half of your total energy from the sun. In fact, you could source around 70% of your energy from solar power without exceeding $100 per MWh; and 90% solar costs around $110 per MWh. As I’ve written previously, AI developers would be unlikely to blink at these prices. For hyperscalers with ambitious carbon commitments — e.g. Microsoft, Google, Amazon, Meta — a premium of less than 30% for 90% zero-carbon power, available in less than three years, is a hell of a good deal. In fact, you might be willing to pay twice as much just to get the thing up & running in that timeframe!

Frankly, when I first read this paper, I wasn’t all that surprised by this conclusion. The authors have made very reasonable assumptions about the current cost of solar, batteries, and gas gensets. And there are clear benefits from keeping a project off-grid — namely avoiding grid interconnection costs, which have risen to an average of more than $200 per kilowatt for solar projects in the US. That can be more than 20% of the total installed cost of solar. Just as importantly, going off-grid means avoiding the long timelines associated with major grid infrastructure projects. On average, sadly, it still takes about ten years to plan & build a transmission line of any consequence here in the US.

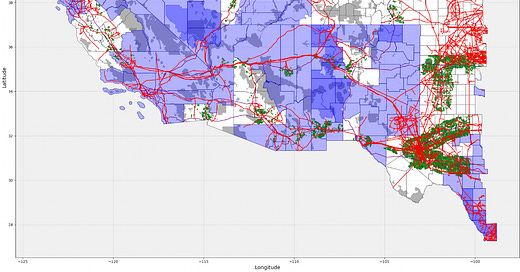

So, what surprised me wasn’t the attractiveness of this off-grid strategy. What surprised me was the scale of this opportunity. Paces AI’s contribution to the paper was determining how many sites there are in the US Southwest which could theoretically support large data centers with enough neighboring land to build sufficient solar & battery storage. Crucially, they screened out sites that could never be viable for practical reasons. For example, they only included sites within 30 miles of airports & highways (to ensure access to sufficient staff and equipment); and sites with plenty of natural gas supply (within 10 miles of interstate pipelines); and they avoided protected land, overly sloped land, and land that encroaches on property setbacks.

And they still identified 1,294 Gigawatts (!) worth of viable sites capable of supplying a large data center with 90% solar power. For context, last year electricity demand in the US peaked at just about 745 GW. In sum: there are enough good sites in the Southwest to build mostly-solar-powered data centers that would exceed the consumption of entire US electricity grid.

One important caveat: It’s almost certainly unrealistic for so much data center capacity to be clustered so far from most major population centers. My understanding is that communications latency is not very important when it comes to training AI models, but it’s almost certainly important for “inference” — i.e. actually using AI to do stuff. Plunking a bunch of solar-powered AI data centers on the outskirts of Albuquerque is probably fine for ChatGPT users in Albuquerque, but not so fine for ChatGPT users in Boston. If a data center developer wants the flexibility to employ the same facility for both training and inference, West Texas is probably not an ideal location. Towards the end of the “Fast, Scalable” white paper, the authors rhetorically question their conclusions about the attractiveness of the remote data center strategy: “If this is so great, why isn’t it happening?” I suspect that this latency problem is one of the biggest sticking points.

Off-grid energy beyond data centers

As excited as I am about AI — which is only kinda sorta excited4 — this analysis got me thinking way beyond data centers.

While I’m somewhat skeptical of the value of LLMs and their ilk, I’m downright passionate about lower-carbon manufacturing and the re-industrialization of America. And the thing is, this “Fast, Scalable” analysis is just as applicable to manufacturing facilities as it is to data centers… if not more so. From an energy consumption standpoint, a data center is basically just a big box with a power supply and a high load factor; and that description could just as well be applied to all kinds of other manufacturing plants running primarily on electricity. Regular Steel For Fuel readers will know that I’m a big believer in industrial electrification. See:

Can wind turbines self-replicate? (And how will we make beer?)

While transportation costs are important for manufactured goods, they’re often less important than the cost of energy & labor. Counterintuitively, the distance to transport physical goods if often less important than the distance to move data, given the ultra-low-latency requirements of many software applications. Meanwhile, given accelerating progress on industrial automation, I anticipate labor costs continuing to fall as a share of the total cost of production. After all, if AI is going to be as transformational as its most prominent boosters hope, it had damn well better reduce the cost of building real, physical things.

That leaves energy. Industry has always been drawn towards places where primary energy is cheap & abundant. My bet is that this gravitational pull will become stronger in the decades to come. As the global economy (hopefully) becomes more carbon constrained, I can envision the Southwest — with good sites for thousands of mostly-solar-powered industrial facilities — blossoming into a major manufacturing hub.

Actually, this vision may not require much of a carbon constraint at all…

The thing is, this “Fast, Scalable” analysis is based on present day costs for solar and lithium-ion batteries. While there is unfortunately significant potential for cost escalation in these markets — mostly owing to trade conflict with China — I still see even more potential for continued cost reduction, as technology advances.

On the storage front in particular, two of our portfolio companies at Energy Impact Partners have demonstrated tremendous potential to lower the cost of operating a system with 90% solar penetration, or higher. Form Energy’s iron-air batteries can store multiple days worth of energy for less than a tenth of the installed cost of lithium-ion systems. And Rondo Energy’s “heat battery” solution can also achieve ultra-low cost while storing energy as high temperature heat — an ideal medium for most industrial processes. See:

Four ways to store sunlight

Moreover, most industrial facilities don’t require such extraordinarily high uptime as data centers. For some, 90-95% “firm” energy supply — as long as it’s not interrupted unexpectedly — may be good enough. That means many industrial facilities can probably get away with less natural gas generation capacity, and therefore achieve an even lower total cost of energy with a sufficient level of reliability.

Will the lowest-cost, lowest-carbon industry be off-grid?

I think it’s possible. The combination of continued progress on solar & storage technology (mostly just storage) and some amount of tolerance for planned outages could lead to tantalyzingly low-cost, low-carbon off-grid power. ($30-50 per MWh is probably not out of the question, in my opinion, but roughly $60 per MWh is a more reasonable expectation.)

America is well positioned to take advantage of this opportunity. Given our status as a natural gas superpower, we already have the resources and the infrastructure in place for gas to serve as the foundation (and “backstop fuel”) for these kinds of industrial microgrids. But it’s our solar (and wind) resources which could enable us to seize the mantle of a clean manufacturing superpower in the decades to come.

Note: I was an early reviewer on this paper.

NERC = North American Electric Reliability Corporation

Note: This white paper assumes that a facility running on small, modular gas generators needs 25% extra capacity in order to guarantee uptime.

It’s complicated. I’m a skeptic of the value of building ever-larger LLMs and related multi-modal models. I find myself convinced by the theory that scaling laws are not going to hold up, and therefore we’re seeing pretty close to the best that the current AI paradigm is going to get. However, I still think there’s a tremendous amount of untapped value left in machine learning, of all flavors, in a wide range of applications.